Double Acting Pneumatic Actuator 3400

Application

General use : Pulp production, water, water treatment, waste water, chemical industry (powder or crystalizing products), win-producing, pulverized products (cement work, pneumatic transport, stocking).

General Characteristics

- Function ON/OFF or regulation

- Wafer threaded mounting ISO PN10

- Unidirectional tightness, direction indication thanks to the arrow on the body

- Small retention zone: the gate is guided in the body and has little clearance

- glad assembly: packing and O-ring (same material as seat joint) to assure the elasticity and decrease the operating force

- Small head loss

- Possibility to regulate thick fluids the adaption of a diaphragm ring.

Construction

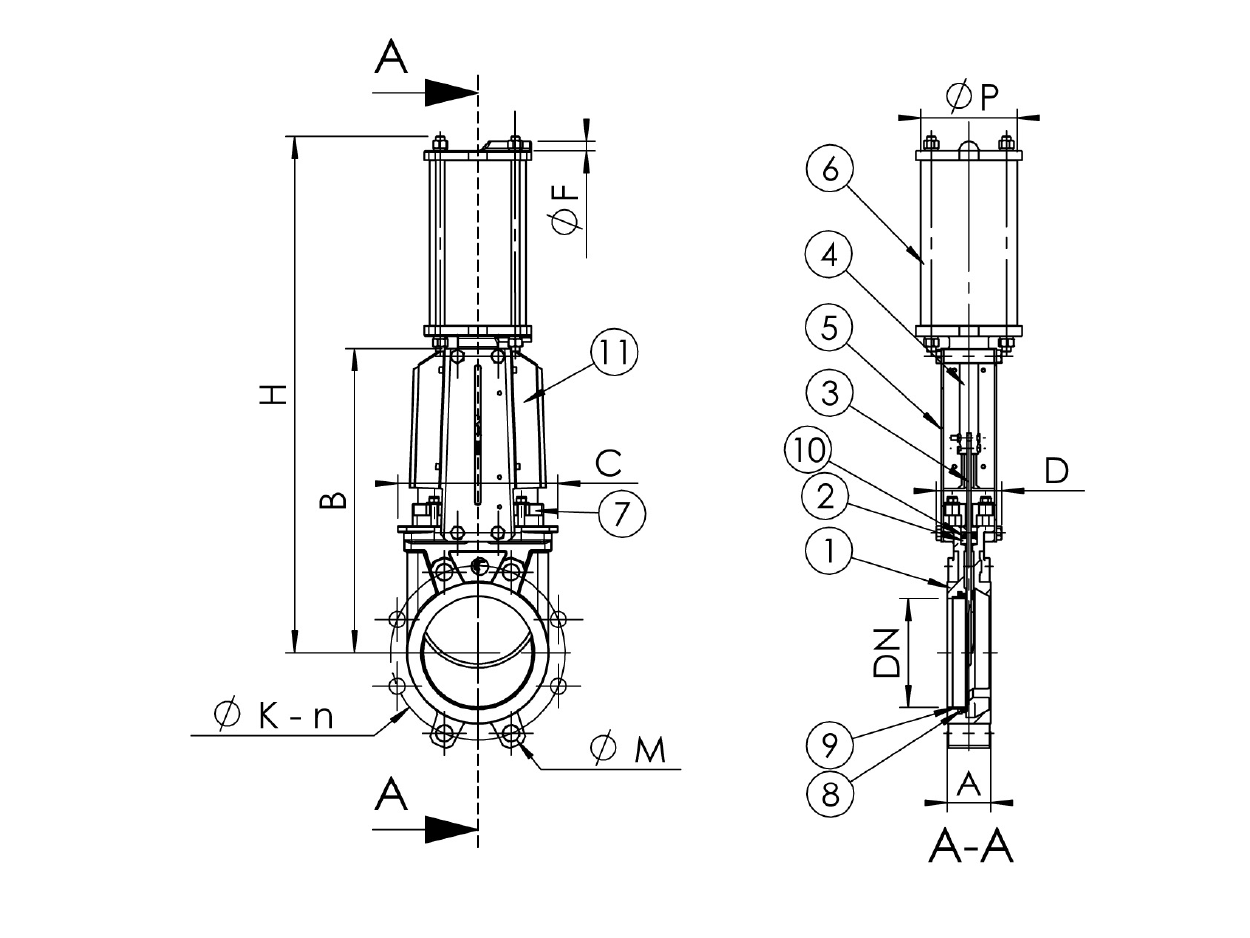

| 11 | 2 | Protection plate | Stainless steel 304 | DIN : X5CrNi 18-10 ASTM : AISI 304 BS : 304 S15 |

| 10 | 1 | O-ring | Nitril | |

| 8** | 1 | Support ring | Stainless steel 316 | DIN : X5CrNiMo18 10 ASTM : A 182 AIS 3 16 BS : 316 S16 |

| 8** | 1 | Gasket | Nitril | |

| 7 | 1 | Packing gland | Alimunium DN50-450 Steel DN500-1200 |

|

| 6 | 1 | Pneumatic actuator | Alimumium | |

| 5* | 2 | Support plate | Steel + epoxy | |

| 4 | 1 | Stem | Stainless steel 13%Cr | |

| 3 | 1 | Knife gate | X5CrNi 18-10 | DIN : X5CrNi 18-10 ASTM : AISI 304 BS : 304 S15 |

| 2 | 2 | Packing | PTFE | |

| 1 | 1 | Body | EN-GJL-250 | DIN : GG 25 ASTM : A48 class 40B BS : 1452 Grade 250 |

| Pos. | Qty. | Description | Material | |

* Pre-shaped parts up yo DN 300

** Missing parts on metal / metal tightness

Dimensions

| DN | ||||||||||||

| mm | inch | A | B | C | D | Ø F | Ø P | H | Ø K | n | Ø M | Weight (kg) |

| 50 | 2″ | 40 | 240 | 124 | 83 | 1/4″ | 80 | 412 | 125 | 4 | 4-M16 | 7,5 |

| 65 | 2″1/2 | 40 | 265 | 139 | 83 | 1/4″ | 80 | 458 | 145 | 4 | 4-M16 | 7,8 |

| 80 | 3″ | 50 | 290 | 154 | 83 | 1/4″ | 80 | 502 | 160 | 8 | 4-M16 | 8,4 |

| 100 | 4″ | 50 | 335 | 174 | 83 | 1/4″ | 100 | 562 | 180 | 8 | 4-M16 | 12,5 |

| 125 | 5″ | 50 | 373 | 189 | 93 | 1/4″ | 125 | 642 | 210 | 8 | 4-M16 | 16,4 |

| 150 | 6″ | 60 | 424 | 220 | 93 | 1/4″ | 125 | 718 | 240 | 8 | 4-M20 | 20,5 |

| 200 | 8″ | 60 | 533 | 275 | 108 | 1/4″ | 160 | 882 | 295 | 8 | 4-M20 | 35,8 |

| 250 | 10″ | 70 | 625 | 326 | 108 | 1/4″ | 200 | 1044 | 350 | 12 | 8-M20 | 52 |

| 300 | 12″ | 70 | 732 | 380 | 108 | 1/4″ | 200 | 1164 | 400 | 12 | 8-M20 | 72 |

| 350 | 14″ | 96 | 835 | 438 | 290 | 3/8″ | 250 | 1362 | 460 | 16 | 10-M20 | 129 |

| 400 | 16″ | 100 | 945 | 494 | 290 | 3/8″ | 250 | 1542 | 515 | 16 | 10-M24 | 144 |

| 450 | 18″ | 106 | 1040 | 547 | 290 | 3/8″ | 250 | 1677 | 565 | 20 | 14-M24 | 177 |

| 500 | 20″ | 110 | 1150 | 613 | 290 | 1/2″ | 320 | 1815 | 620 | 20 | 14-M24 | 268 |

| 600 | 24″ | 110 | 1354 | 716 | 290 | 1/2″ | 320 | 2130 | 725 | 20 | 14-M27 | 351 |

| 700 | 28″ | 110 | 1540 | 835 | 320 | 1/2″ | 426 | 2488 | 840 | 24 | 16-M27 | 556 |

| 800 | 32″ | 110 | 1750 | 972 | 320 | 1/2″ | 426 | 2798 | 950 | 24 | 16-M30 | 679 |

| 900 | 36″ | 110 | 1990 | 1041 | 320 | 1/2″ | 538 | 3162 | 1050 | 28 | 20-M30 | 840 |

| 1000 | 40″ | 110 | 2195 | 1152 | 320 | 1/2″ | 538 | 3452 | 1160 | 28 | 20-M33 | 1053 |

| 1200 | 48″ | 150 | 2390 | 1255 | 400 | 1/2″ | 538 | 4048 | 1380 | 32 | 22-M36 | |

Working Conditions

Maximum working pressure:

| DN 50-250 | 10 bar |

| DN 300-450 | 7 bar |

| DN 500-600 | 4 bar |

| DN 700-1200 | 2 bar |

Maximum temperature: -10°C / +80°C

| Others materials on request (if marked) | Maximum temperature |

| Metal / metal | T max : -10°C / +80°C |

| White NBR | T max : -10°C / +80°C |

| EPDM | T max : -10°C / +130°C |

| Silicone | T max : -10°C / +170°C |

| FPM (Type Viton(®)) | T max : -10°C / +170°C |

| PTFE*** | T max : +4°C / +170°C |

| CSM (Type Hypalon(®)) | T max : +4°C / +80°C |

*** Minimum working pressure : 1 bar